Quality control

Quality starts in the design phase! Hetitec’s casting experts will help you design parts with good castability from the correct materials. We want to make sure that your casting is suited for its intended use.

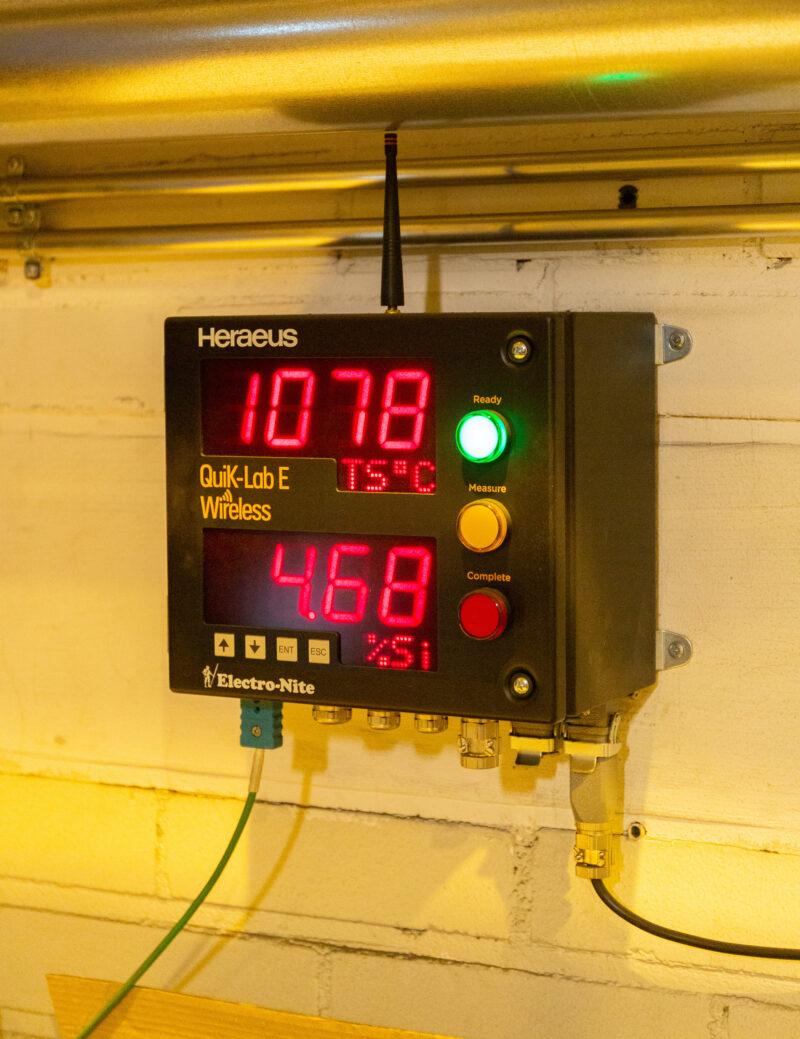

We use a number of methods to ensure that the quality of the melt and the material parameters of our castings are on point. Starting from clean raw materials, a high-quality end product is inevitably the result of a careful, professional inspection process. Every melt we do is carefully analyzed with optical emission spectroscopy to ensure correct chemical analysis. Additionally, we use thermal analysis to determine the carbon, carbon equivalent, and silicon content in all of our cast iron melts.

Finally, we verify the quality of the final parts through various quality assurance tests. We use both destructive methods – such as impact, elongation, and tensile strength testing – and nondestructive methods, like x-ray, ultrasound, magnetic particle, and penetrant testing.

When the product is carefully designed, casting features optimized, professionally cast, machined if needed, and finally, subjected to careful quality control — the result is a part that fulfills all your specifications to the highest of standards.